Skimming Tank – have you come across this term before?

As we all know that the wastewater treatment is one of the most critical processes for safeguarding environmental health, protecting aquatic ecosystems, and maintaining public hygiene. Whether it comes from households, industries, or commercial establishments, wastewater contains a variety of contaminants—solids, dissolved substances, and floating materials such as oil, grease, and scum. If these floating impurities are not removed early in the treatment process, they can clog pipelines, damage pumps, and reduce the efficiency of subsequent treatment stages.

This is where skimming tanks play a vital role. Positioned in the primary treatment stage, they are specifically designed to remove lighter-than-water substances from the wastewater surface, improving the overall performance and longevity of the treatment system.

What is a Skimming Tank?

This video explains the process of waste water management using skimming tanks –

A skimming tank is a specially designed chamber in which wastewater is held under calm conditions, allowing oils, fats, grease, and other floating solids to rise to the surface due to their lower density compared to water.

These materials are then physically removed by skimming devices—either manually or automatically. Skimming tanks act as protective shields for downstream units such as sedimentation tanks, aeration basins, and filters, which are more effective when free from floating contaminants.

Purpose or Use of Skimming Tanks in Wastewater Treatment

The primary purposes of a skimming tank include –

1) Protecting equipment

A skimming tank protects equipment by capturing oils, grease, and debris that could damage pumps, clog pipes, or foul filtration systems. By removing these materials upfront, it extends the lifespan of downstream machinery and reduces costly repairs.

2) Improving treatment efficiency

It improves treatment efficiency by eliminating floating waste early in the process, preventing clogs and overloading in downstream equipment. This ensures smoother operation, reduces maintenance needs, and enhances the overall performance of the wastewater treatment system.

3) Preventing pollution

A skimming tank helps reduce pollution by removing floating oils, grease, and light solids from wastewater before it’s discharged or treated further. This prevents harmful contaminants from entering natural water bodies, protecting aquatic life and improving overall water quality.

4) Reducing operational costs

A skimming tank reduces operational costs by preventing equipment damage, minimizing blockages, and lowering maintenance frequency. This leads to fewer repairs, less downtime, and more efficient wastewater treatment, ultimately saving energy and labor expenses.

For industries such as oil refineries, food processing units, and textile mills, the removal of oily matter is not just desirable—it’s a legal requirement under environmental discharge regulations.

What are the Components of a Skimming Tank?

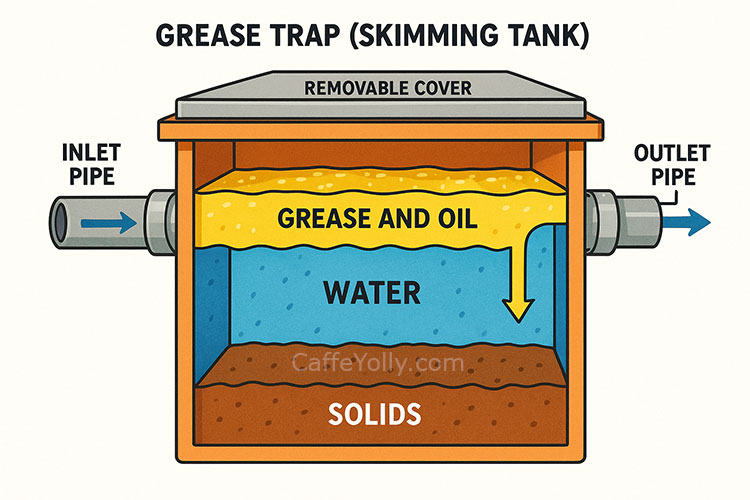

A skimming tank is made up of several essential components that work together to remove floating impurities such as oil, grease, and debris from wastewater. These components include:

- Inlet Chamber – Guides the incoming wastewater into the tank and distributes flow evenly to allow effective separation.

- Baffles – Vertical plates that slow down water movement, encouraging oils, grease, and light solids to rise to the surface.

- Skimming Mechanism – Can be a mechanical arm, rotating weir, or fixed skimmer that pushes floating matter toward the collection area.

- Oil and Scum Collection Trough – Receives and stores the skimmed material before it is removed for disposal or recycling.

- Outlet Chamber – Ensures that only treated water passes to the next stage of wastewater treatment, preventing floating waste from escaping.

- Sludge Hopper – Collects heavier particles that settle at the bottom, preventing them from clogging the system.

- Drain Valves – Allow periodic removal of sludge and maintenance of the tank.

By working in combination, these components maximize the efficiency of waste removal, protect downstream equipment, and ensure the smooth operation of wastewater treatment systems.

How Does the Skimming Tank Work – Working Principle

A skimming tank works on the principle of gravity separation to remove floating impurities like oil, grease, and light solids from wastewater. Since these materials are lighter than water, they naturally rise to the surface, where they can be skimmed off. The process involves the following steps:

Inflow of Wastewater – Wastewater enters the inlet chamber, where its flow is slowed down to allow separation to begin.

Gravity Separation – Due to density differences, oils, grease, and floating solids move upward, while heavier solids settle at the bottom.

Baffle Action – Baffles control the water flow, preventing turbulence that could mix separated waste back into the water.

Skimming Operation – A mechanical arm, rotating weir, or fixed skimmer pushes the surface waste toward the oil and scum collection trough.

Collection & Removal – The collected impurities are stored in a trough or compartment for manual or automated removal.

Clean Water Outflow – Treated water exits via the outlet chamber, ready for further treatment stages.

By harnessing natural buoyancy and controlled water flow, skimming tanks provide an efficient, low-energy method for removing floating contaminants from wastewater.

What are the Types of Skimming Tanks?

Skimming tanks are designed in various forms to suit different wastewater treatment needs, and each type has unique operational features. The most common types include:

1. Fixed Weir Skimming Tanks

These use a stationary overflow weir to collect floating oils and grease. Wastewater flows over the weir, and contaminants are guided into a collection trough. They are simple, cost-effective, and require minimal maintenance.

2. Rotating Weir Skimming Tanks

Equipped with a movable weir or arm that rotates slowly across the tank’s surface, these systems continuously skim off floating materials. They provide more uniform coverage, making them ideal for larger treatment plants.

3. Chain and Flight Skimming Tanks

A continuous chain mechanism drags skimming blades (flights) across the water’s surface, pushing floating debris toward a collection area. This design is durable and suitable for heavy-duty industrial applications.

4. Paddle-Type Skimming Tanks

Paddle arms rotate across the water, gently moving surface waste toward the outlet. These are often used where delicate handling of floating waste is needed.

Choosing the right type depends on wastewater characteristics, plant size, and maintenance requirements, ensuring optimal performance and efficiency in removing floating pollutants.

Applications in Wastewater Treatment

Skimming tanks play a vital role in a wide range of wastewater treatment applications by efficiently removing floating contaminants before they can affect downstream processes. In municipal wastewater treatment plants, they are used to separate oils, grease, plastics, and floating solids from sewage, preventing clogging and enhancing the efficiency of biological treatment stages. In industrial wastewater treatment, such as in food processing, petroleum refining, textile, and chemical plants, skimming tanks capture process oils, fats, and lightweight solids, reducing chemical usage in later treatment stages. In stormwater treatment systems, skimming tanks help remove floating debris, leaves, and hydrocarbons from runoff, preventing pollution in natural water bodies.

In slaughterhouses and meat-processing plants, they are essential for separating animal fats and organic matter from wastewater to meet discharge regulations. Additionally, in oil-water separation facilities, they provide the first stage of treatment by isolating petroleum products from water. By preventing the entry of floating waste into secondary treatment units, skimming tanks extend equipment life, maintain hydraulic capacity, and reduce the risk of environmental contamination. Their versatility and effectiveness make them a key component in both primary treatment systems and specialized industrial wastewater applications, ensuring compliance with environmental standards.

What are the Advantages of Skimming Tanks

Skimming tanks provide several advantages in wastewater treatment by enhancing efficiency, protecting equipment, and supporting environmental safety. They effectively remove floating contaminants such as oils, grease, scum, plastics, and other buoyant debris before these materials enter downstream processes. This improves the performance of biological and chemical treatment stages, ensuring higher-quality treated water.

By preventing clogging and fouling, skimming tanks protect pumps, pipes, and filters, extending their lifespan and reducing maintenance needs. This directly lowers operational costs by minimizing downtime and repair expenses. Their role in preventing harmful substances from being discharged into natural water bodies also ensures compliance with environmental regulations. Skimming tanks are versatile, suitable for municipal, industrial, and stormwater treatment applications.

Additionally, they are energy-efficient, as most designs operate with minimal mechanical parts, and their simple construction allows for easy cleaning and maintenance. Overall, skimming tanks contribute to a more reliable, cost-effective, and eco-friendly wastewater treatment process.

What are the Limitations of Skimming Tanks?

Skimming tanks, while highly useful, do have certain limitations that can affect their efficiency and suitability in wastewater treatment. They are primarily designed to remove floating materials such as oils, grease, and lightweight solids, meaning they are ineffective for heavier particles or dissolved contaminants that require other treatment methods. Their performance can be influenced by flow rate fluctuations—high inflow velocities may cause floating matter to pass through without being removed. In some cases, emulsified oils or very fine particles cannot be separated without additional chemical treatment or advanced separation techniques.

Skimming tanks also require regular cleaning to prevent odor generation and maintain efficiency, which can increase labor needs. In industrial applications with large amounts of floating waste, their size and space requirements can be significant. Additionally, they are only a preliminary treatment step and must be integrated with other processes like sedimentation, filtration, or biological treatment for complete wastewater purification. Therefore, while skimming tanks are valuable, they cannot be relied on as a standalone solution for all wastewater challenges.

Maintenance and Safety of Skimming Tanks

Proper maintenance and safety practices are essential for the effective operation of skimming tanks. Regular inspection and cleaning are required to prevent the buildup of oils, grease, and debris that can reduce efficiency and cause odors. Operators should follow scheduled desludging and check mechanical components, such as scrapers or skimmers, for wear and tear. Safety measures include ensuring that tanks are covered or fenced to prevent accidental falls, wearing protective gear during cleaning, and providing adequate ventilation to avoid exposure to harmful gases. Adhering to maintenance schedules and safety protocols ensures long-lasting performance and minimizes operational risks.

Conclusion

Skimming tanks may appear simple compared to advanced treatment units, but their role in wastewater treatment is indispensable. By removing floating oils, grease, and scum early in the process, they not only improve the efficiency of downstream processes but also reduce operational costs and environmental risks.

With modern automation, skimming tanks are becoming more efficient, requiring less manual labor while offering higher removal rates. As industries face stricter environmental regulations, investing in a well-designed skimming tank is both a compliance necessity and an operational advantage.